Early planning is critical to ensure a successful scale-up, but it is important to incorporate flexibility into these plans. Demand can often be a moving target, and production may have to adjust as forecasts change. Make a plan, but be ready to react.

Production planning should be integrated into early design phases. There are many factors to consider, such as capital investments and the overall timing. In addition, manufacturing, like design, is an iterative process. Initial yields may be lower than anticipated and will need to be ramped up. While planning, factor in non-production activities, such as set-up and line clearance, which can reduce yields.

Many inputs go into estimating manufacturing capacity. Most calculations assume 7-hour shifts, with time for lunch and other breaks. Provisions for yield will also improve the quality of your estimate. Using a typical manufacturing model that estimates a 3-second cycle time, with a 7-hour shift and an 85 percent yield provides a good starting point for your model. But, consider making adjustments based on your product and maturity of the manufacturing line.

Planning POC consumable scale-up?

How you handle planning integration throughout the design process is critical to seamless transfer to manufacturing. We can help.

GET IN TOUCH

When calculating capacity, factor in workflow setup before production. This may include line clearance time to reduce cross-contamination risks, system cleaning, and independently verifying each batch. Workflow setup may also include off-line activities, including reagent preparation and quality control (QC) and complete release acceptance testing.

It is also important to determine early on which components and processes will be manufactured and conducted in-house, and which ones will be contracted to third parties. If third-party support is necessary, you need to plan for additional time to form those partnerships.

The appropriate vendor(s) must be selected by striking the right balance between capabilities, cost, quality, proximity and any other product-specific factors. Adequate time allowances need to be included to qualify suppliers and negotiate appropriate supply agreements.

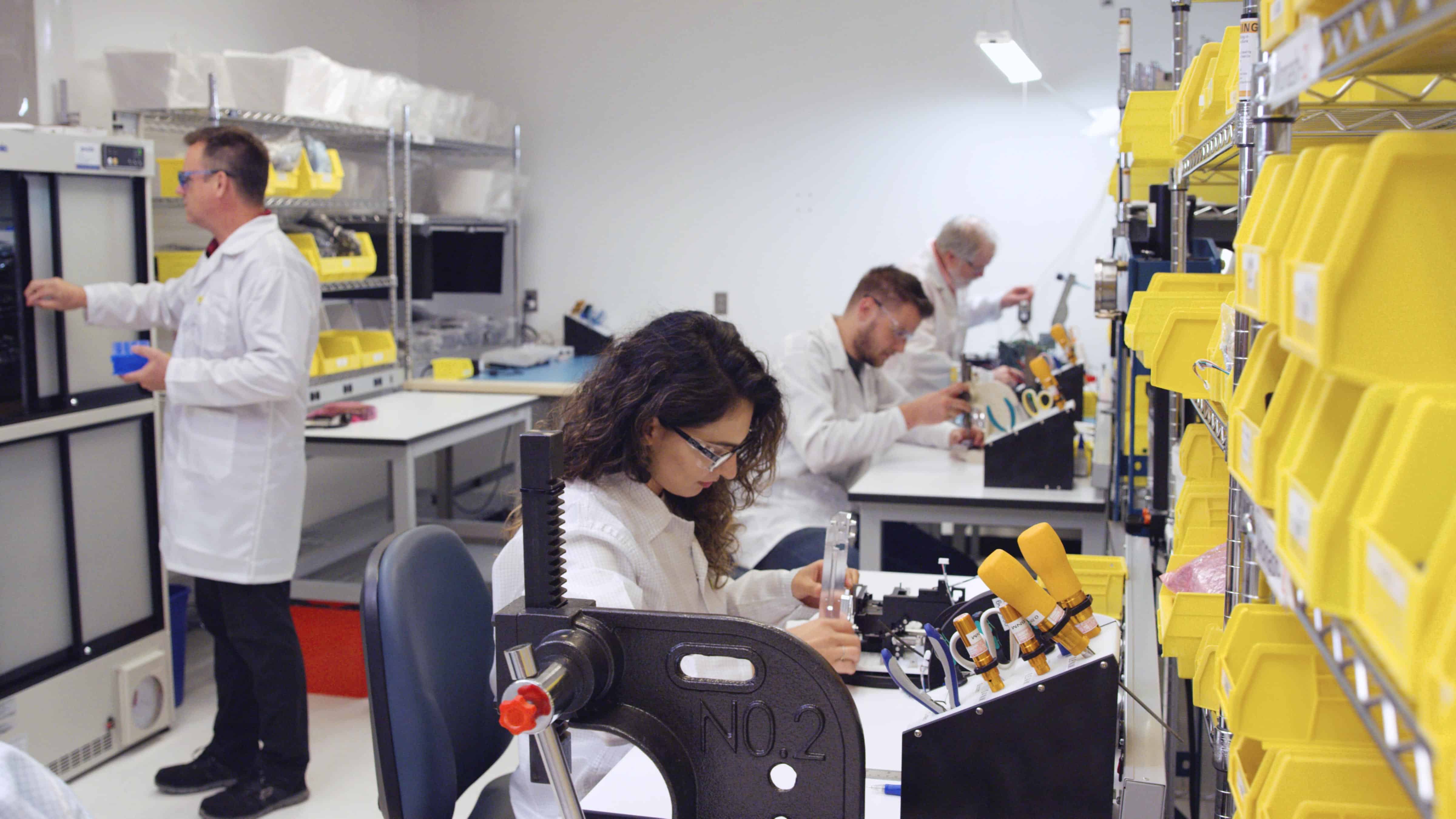

Early in development, when volumes are much lower, manually dispensing small reagent batches into cartridges can meet demand. However, as batch sizes ramp up for validation testing and clinical trials, you must move to a high-volume process.

To get there, you must:

- Automate and scale-up low volume lines

- Replicate production lines to account for down-time redundancy and higher volume needs

- Build in development and engineering support

- Develop modular production line sections to rapidly scale around bottlenecks

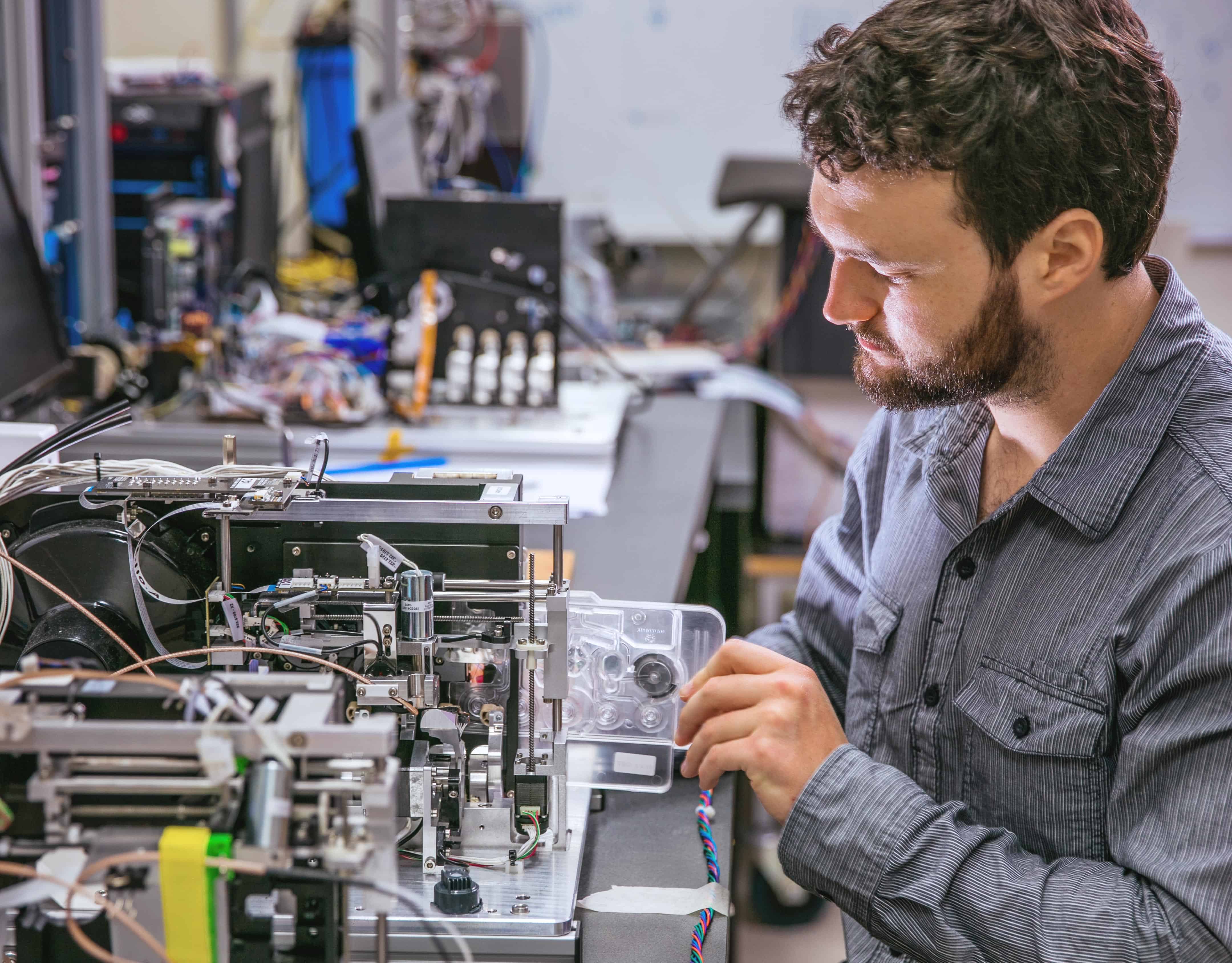

One key task – early in system design – is developing a representative production process that demonstrates how you will consistently produce high-quality cartridges at projected volumes.

One key task – early in system design – is developing a representative production process that demonstrates how you will consistently produce high-quality cartridges at projected volumes.