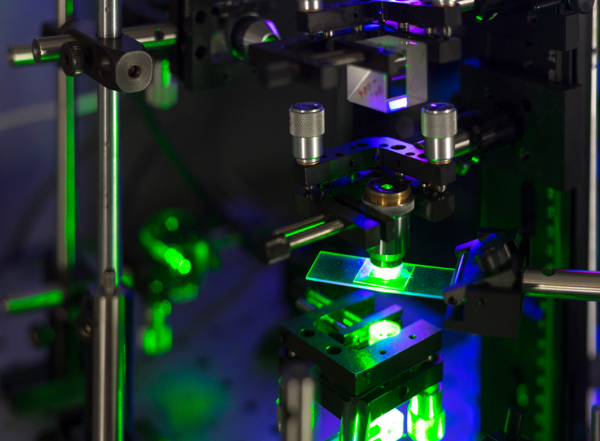

Invetech has unparalleled expertise in this area, overcoming all sorts of motion challenges, from controlling motion at the nanometer level to driving high frame rates and critical focus in automated imaging systems.

A common challenge across projects in diagnostics and life sciences is the requirement for motion and motion control for liquid handling, imaging, optics, focusing, and positioning. We ensure the successful integration of subsystems and test solutions under real-world conditions of the intended product environment to ensure reliable motion implementation.

- Precision Motion <10um

- Centrifugation

- Internal Transport

Capturing an image of ten-thousand cells, moving a microliter of high value reagent or manipulating magnetic particles, at speed, reliably, and robustly for years of operation is made possible through the implementation of a well-engineered precision motion system.

The range of factors that can impact performance in the single-digit micrometer motion range grows rapidly.

Items such as:

- Thermal expansion

- Hysteresis, backlash

- Applied load

- Abbé error

- Mechanical stiffness

- Runout

- Bearing vs positioning accuracy and more, all affect system accuracy and repeatability.

Separating proteins from DNA, maintaining solution homogeneity or moving consumables are all applications that typically require rotational motion. The design of a rotational system is guided by factors such as:

- Throughput (Speed & Acceleration)

- Payload

- G-force for centrifugal applications

- Applied loads and torques

- Control method (position, velocity, torque etc)

- Strength & stress

The range of technical implementations for rotational motion systems is vast with many options for motors, linkages, bearings/bushings, cooling and lubrication. Invetech’s motion system experts would love to work with you to select, customise or develop a solution which optimally meets your performance, schedule and budget needs.

Moving materials within a product, whether a door, an opening, clamping in place, piercing, consumable handling etc. all typically involve robots of some description. Systems that achieve these motions may be implemented by a simple, single-axis such as a belt and rail or a more complex synthesis of many axes such as a linear motor XYZ stage depending on the system requirements.

Invetech has wide experience in axis design for internal transport systems. We have modular single and multi-axis designs that can be leveraged for typical applications, or we can engineer a full mechatronic system that meets more unique performance and budget needs.

Our solutions aren’t limited to any specific implementation, we have utilized components such as cams, gears, rails, belts, flexures, slides, bushings, stepper motors, linear motors, piezos and more to achieve any motion need.

- Precision Motion <10um

- Centrifugation

- Internal Transport

Capturing an image of ten-thousand cells, moving a microliter of high value reagent or manipulating magnetic particles, at speed, reliably, and robustly for years of operation is made possible through the implementation of a well-engineered precision motion system.

The range of factors that can impact performance in the single-digit micrometer motion range grows rapidly.

Items such as:

- Thermal expansion

- Hysteresis, backlash

- Applied load

- Abbé error

- Mechanical stiffness

- Runout

- Bearing vs positioning accuracy and more, all affect system accuracy and repeatability.

Separating proteins from DNA, maintaining solution homogeneity or moving consumables are all applications that typically require rotational motion. The design of a rotational system is guided by factors such as:

- Throughput (Speed & Acceleration)

- Payload

- G-force for centrifugal applications

- Applied loads and torques

- Control method (position, velocity, torque etc)

- Strength & stress

The range of technical implementations for rotational motion systems is vast with many options for motors, linkages, bearings/bushings, cooling and lubrication. Invetech’s motion system experts would love to work with you to select, customise or develop a solution which optimally meets your performance, schedule and budget needs.

Moving materials within a product, whether a door, an opening, clamping in place, piercing, consumable handling etc. all typically involve robots of some description. Systems that achieve these motions may be implemented by a simple, single-axis such as a belt and rail or a more complex synthesis of many axes such as a linear motor XYZ stage depending on the system requirements.

Invetech has wide experience in axis design for internal transport systems. We have modular single and multi-axis designs that can be leveraged for typical applications, or we can engineer a full mechatronic system that meets more unique performance and budget needs.

Our solutions aren’t limited to any specific implementation, we have utilized components such as cams, gears, rails, belts, flexures, slides, bushings, stepper motors, linear motors, piezos and more to achieve any motion need.