MyCartis: Evalution® Multiplex Biomarker Analysis

A revolutionary biomarker analysis platform realizing next-generation personalized healthcare.Client: MyCartis

Product: Evalution®

EXPERTISE

LEVERAGED

Fluidics, Optics, Motion, Software Development, Industrial Design, Thermal Control & Analysis, Contract Manufacturing

Realizing Next-Generation Personalized Healthcare

European-based company MyCartis developed its proprietary Dynamic Multi-Analyte Technology (DMAT®). DMAT® is an advanced and unique technology to deliver superior data quality and rapid results for analyzing multiple protein and nucleic acid-based biomarkers. To close the gap between the user requirements of their target groups and its unique technology, MyCartis invited Invetech to develop a solution around its technology that would be tailored to the clinical research and pharmaceutical markets.

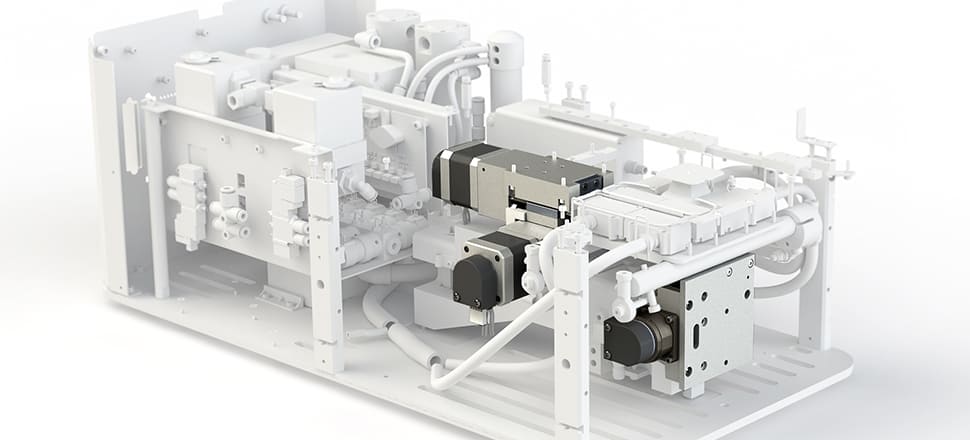

The result of this partnership is the Evalution®

, a multiplex diagnostic platform that provides an integrated reaction and detection environment and simultaneous analysis of large numbers of analytes per assay. The core technology surrounds the imaging and fluorescence reading of 40-micron binary-coded silicon microparticles.

Thousands of different digital codes can be generated and the platform provides fast and highly sensitive detection of a broad range of biomarkers. The flexibility and simplicity of the workflow enables researchers to streamline procedures for biomarker verification and validation, and to accelerate the translation of novel content to clinical practice.

A Close Collaboration

Collaboration was key to the success of Evalution®. We worked very closely with MyCartis as they developed the core technology for the instrument and we handled the instrument design, prototyping, testing and interface definition. Close collaboration also took place between our teams, the client and a microfluidics design partner to ensure trouble-free interfacing between the instrument and the microfluidic cartridge.

During the system integration phases of the project, the Invetech team spent time in Belgium with the MyCartis team to ensure the project goals were met. Additionally, to minimize risk throughout the project, we collaborated on a joint risk watch list and held regular risk watch meetings throughout the development process.

Flexible Processes for Ideal Outcomes

Being a startup with fluctuating demands, MyCartis needed a flexible development partner. During the system definition phase, our flexible processes and open communication created a space for MyCartis to explore ways to give the most promising markets access to their technology

first. We adapted our plans and activities to accommodate their processes and direction shifts while implementing all elements of the design including mechanical, fluidics, optics and software. Precision motion components sourced through our Dover Motion division were also integral to the instrument design

Using Our Experience to Solve New Challenges

Transparency for Better Decision Making

Using our Business Systems, Value Analysis/Value Engineering (VAVE) tools enabled us identify opportunities to reduce the bill of materials as well as labor and design process costs of the instrument. This was done by characterizing

the potential changes in terms of cost impact, technical risk and ease of implementation. These trade-offs were regularly discussed with the client during development so that educated and joint decisions could be made accordingly.

More Case Studies

Below are a selection of case studies highlighting the range of problems we’ve solved to deliver innovation and business value for our clients.

Life Sciences & Biotech

Not all innovative or complex technology is used in the clinic, but these systems benefit from many of the same principles used.

Mid to High Throughput Instruments

Whether we support the entire product or take lead on a subsystem, full instrument architecture is critical to success.

Benchtop & Distributed

Translating technical workflows of an assay into an automated process performed within a device.

Custom Process Automation

Transition from clinical to commercial scale manufacturing with our production-ready manufacturing and automation solutions.