PREVI™ Isola Automated Microbiological Streaking Instrument

Product: Microstreak (marketed by bioMérieux as PREVI™ Isola)

AWARDS

2010 Medical Design Excellence Awards, IVD

REGULATORY

REQUIREMENTS

EN 61010-1, IEC 61010-2-81, UL 61010A-1 & UL 61010-2-010, EN 61326, EN 55011, RoHS

EXPERTISE

LEVERAGED

Fluidics, Motion, Industrial Design, Usability/HFE, Connectivity & Systems Integration, Consumable Design, Contract Manufacturing

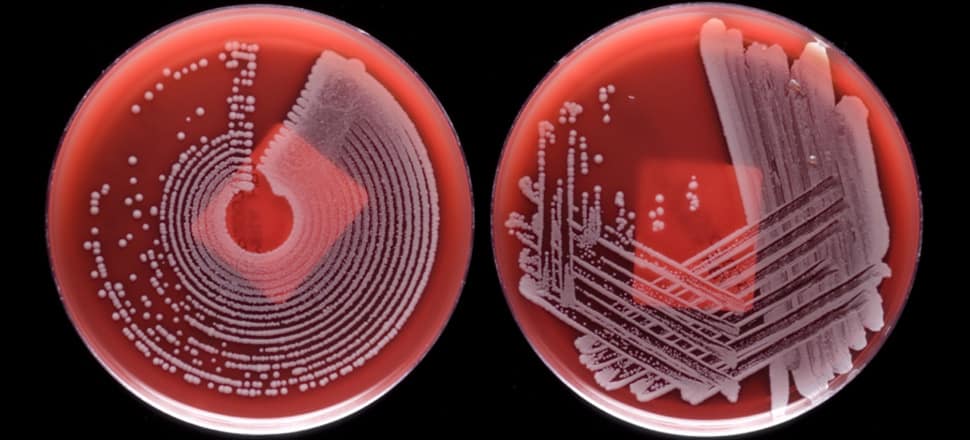

Automating processes to streamline the clinical lab workflow

Conventional clinical microbiology involves specimen collection, registration, inoculation, isolation, identification and testing of pathogenic microbes from clinical specimens. Traditionally, this process has used minimal automation. The isolation of bacterial colonies for identification and antibiotic susceptibility testing is performed manually using handheld spreading devices called “loops” to streak a specimen onto one or more agar plates for incubation. This process is highly labor intensive, produces results of variable quality, and ties up highly skilled and valuable microbiologists by performing routine work in an environment where their skills are in increasing demand.

LabTech Systems developed a revolutionary concept for mechanically streaking microbiological specimens on to conventional agar plates for diagnostic microbiology.

They approached us to develop a concept for high-throughput automation of this core process in clinical laboratories, and then to design and manufacture this instrument.

The technical challenge required us to design a highly robust system to deal with a very wide variety of sample types at high throughput while handling a wide range of agar plate types at high speed and producing reliable and consistent plate streaking.

Our team worked closely with LabTech Systems, and later with bioMérieux, to build on their critical market input to design, develop and manufacture the instrument. The goal was for it to use LabTech’s innovation to automate many of the manual tasks traditionally involved in the preparation of agar plates.

From Concept Development to Contract Manufacturing

During our collaboration with LabTech Systems, we provided:

- Instrument concept generation

- Basic proof of principle for the critical higher risk automation solutions

- Detailed design and development of the instrument (including electronics, fluidics and robotics)

- The instrument control and service software and GUI

- Prototype building, testing and qualification

- Formal instrument Verification to Requirements

- Transfer to manufacturing to our in-house manufacturing facilities

- Ongoing manufacturing support and sustaining engineering

Particular challenges throughout development included creating precision pipetting and positioning functions that could cope with the high variability of agar plates, and providing robustness and ease of use for field deployable applications. The technology within the Microstreak revolutionizes specimen inoculation and front-end processing tasks by: Maximizing bacterial colony isolation and quantification Standardizing plate inoculation processes and results interpretation Streamlining the lab workflow, freeing up skilled staff for high skill activities

More Case Studies

Below are a selection of case studies highlighting the range of problems we’ve solved to deliver innovation and business value for our clients.

Life Sciences & Biotech

Not all innovative or complex technology is used in the clinic, but these systems benefit from many of the same principles used.

Mid to High Throughput Instruments

Whether we support the entire product or take lead on a subsystem, full instrument architecture is critical to success.

Benchtop & Distributed

Translating technical workflows of an assay into an automated process performed within a device.

Custom Process Automation

Transition from clinical to commercial scale manufacturing with our production-ready manufacturing and automation solutions.