Confidential: Multiplex System Pack Cooler

We organized a kaizen continuous improvement exercise that identified an opportunity for cost savings and risk reduction of the pack cooler sub-system. With support from the client, the robustly tested design changes resulted in significant savings per unit.

Client: Confidential

Product: Multiplex Testing SystemSystem

Cost Reduction Though Improvements To Manufacturability

55%

Savings per Unit

Supported by Comprehensive Testing

DESIGN CHANGES

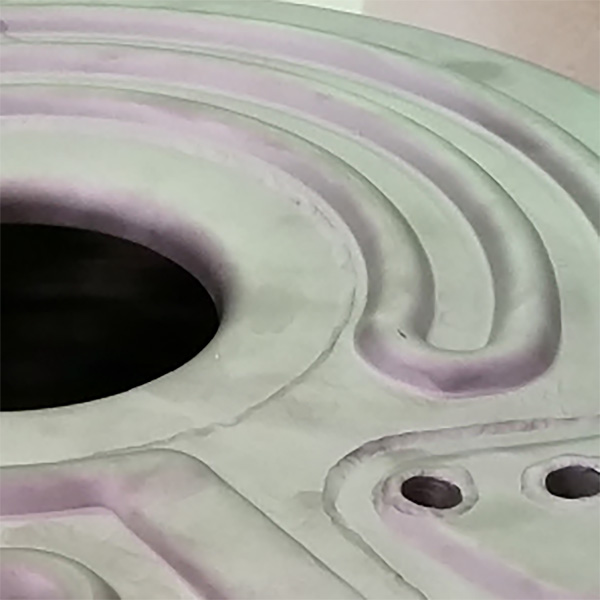

Spun Aluminum Bowl

Updated design replaced the stainless steel double-walled, welded bowl with a simpler spun aluminim bowl. The reduction in required welds also reduced the risk of warranty issues caused by leaks.

Copper Tube Cooling Pipe

More Case Studies

Below are a selection of case studies highlighting the range of problems we’ve solved to deliver innovation and business value for our clients.

Life Sciences & Biotech

Not all innovative or complex technology is used in the clinic, but these systems benefit from many of the same principles used.

Mid to High Throughput Instruments

Whether we support the entire product or take lead on a subsystem, full instrument architecture is critical to success.

Benchtop & Distributed

Translating technical workflows of an assay into an automated process performed within a device.

Custom Process Automation

Transition from clinical to commercial scale manufacturing with our production-ready manufacturing and automation solutions.