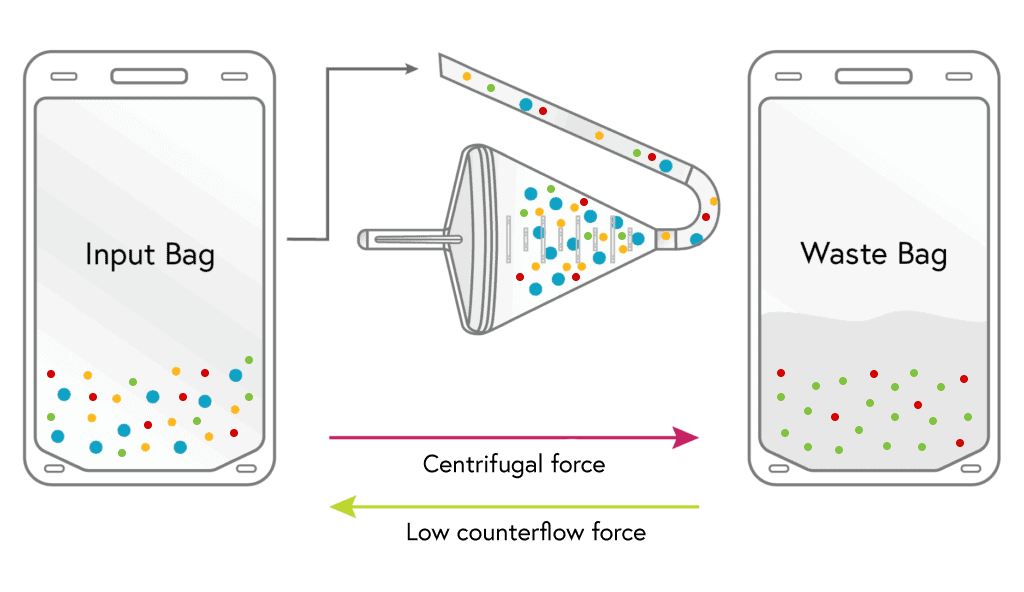

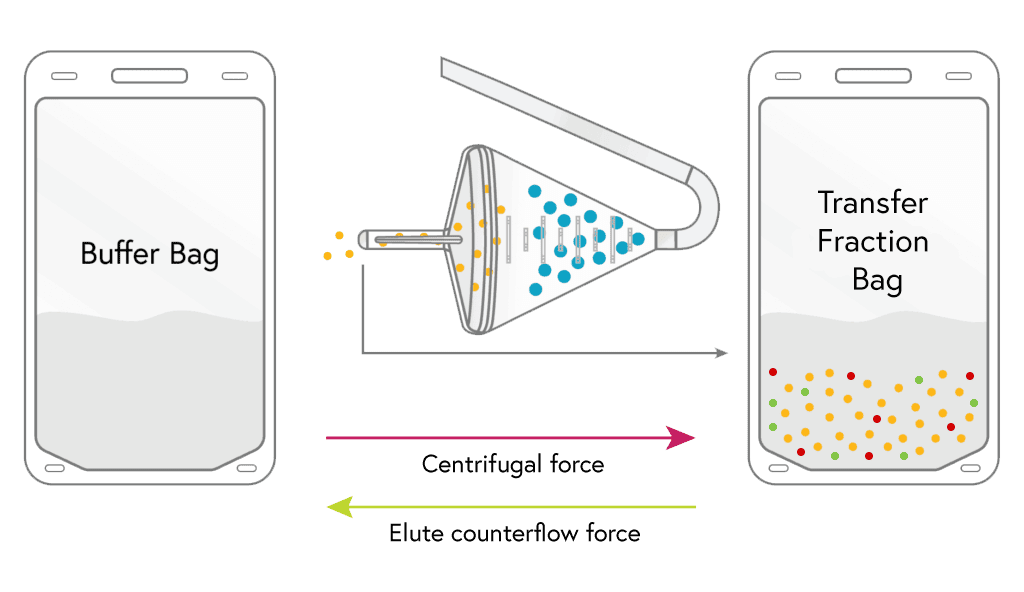

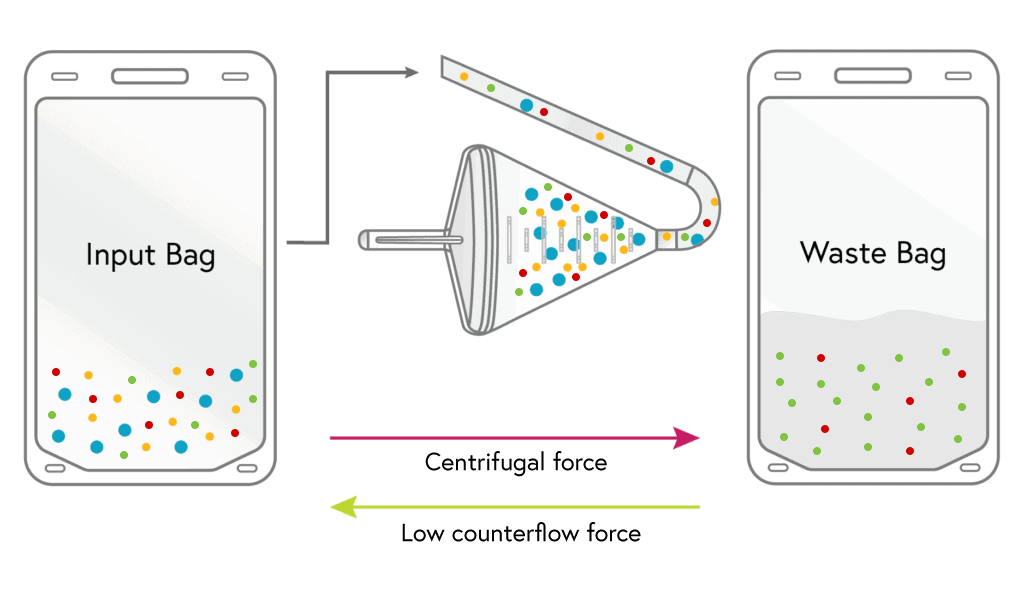

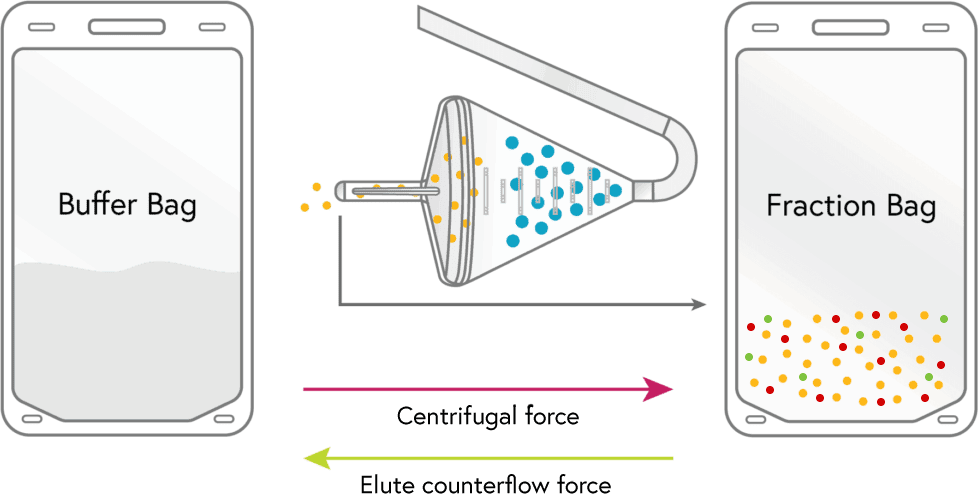

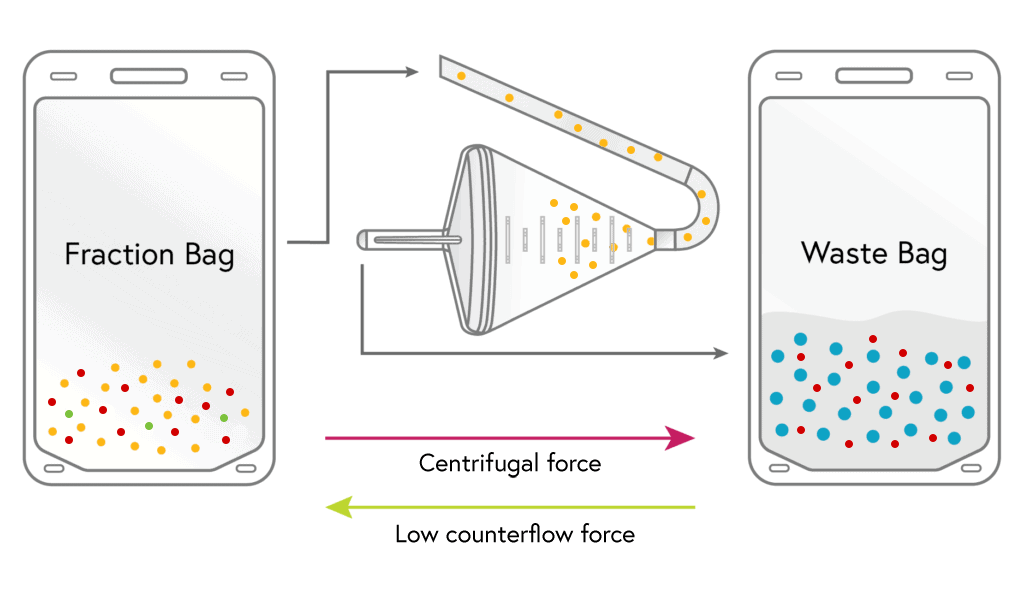

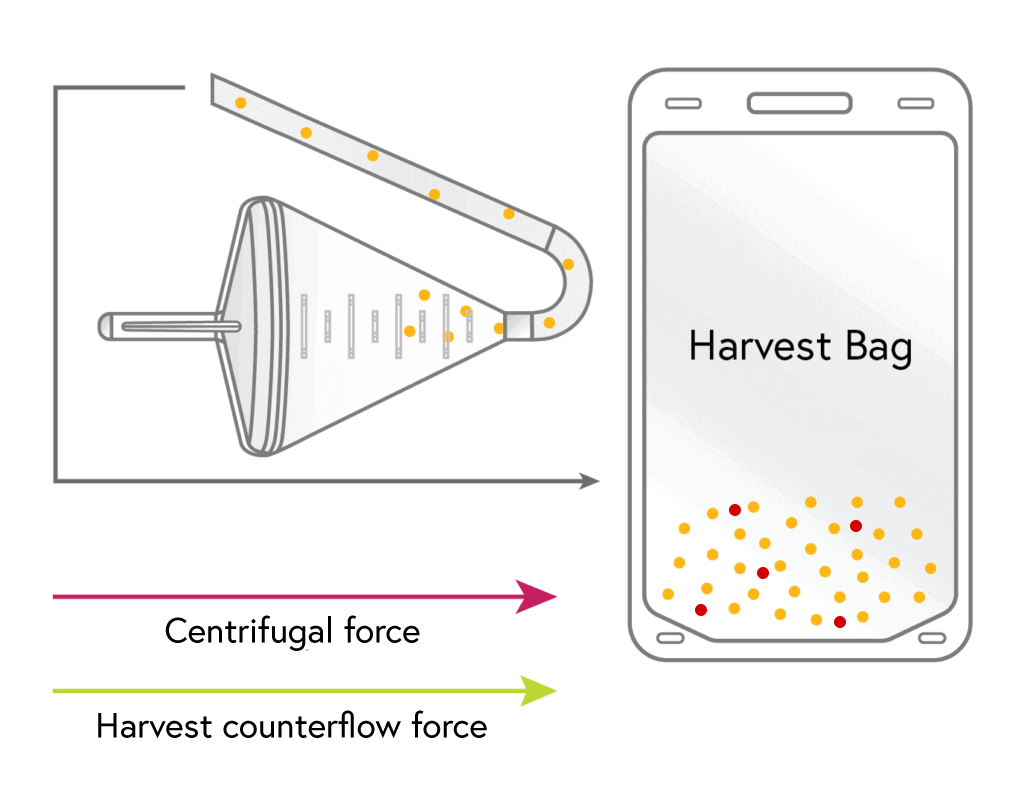

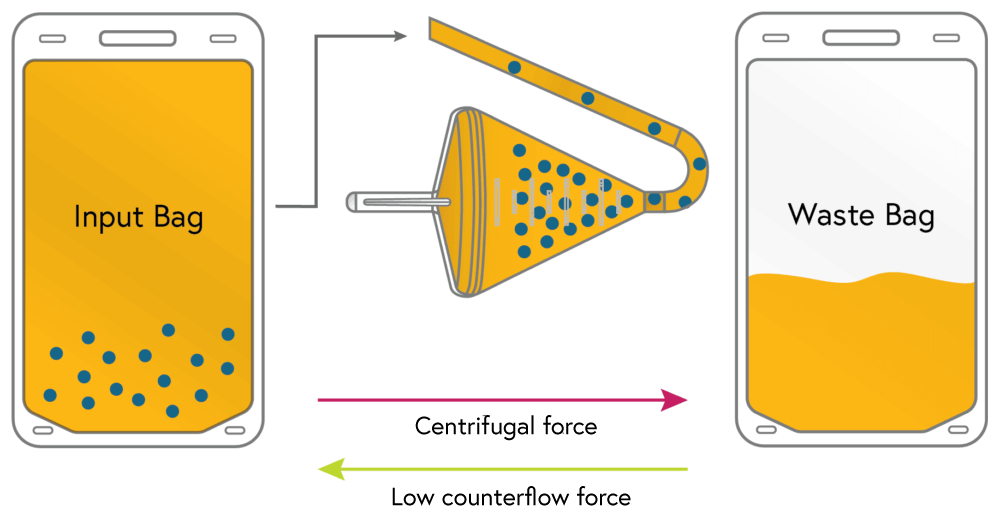

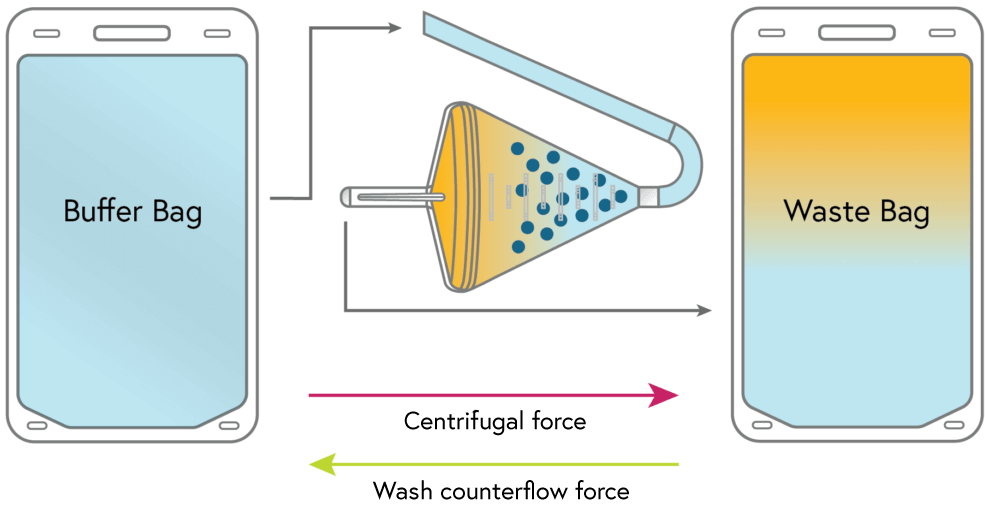

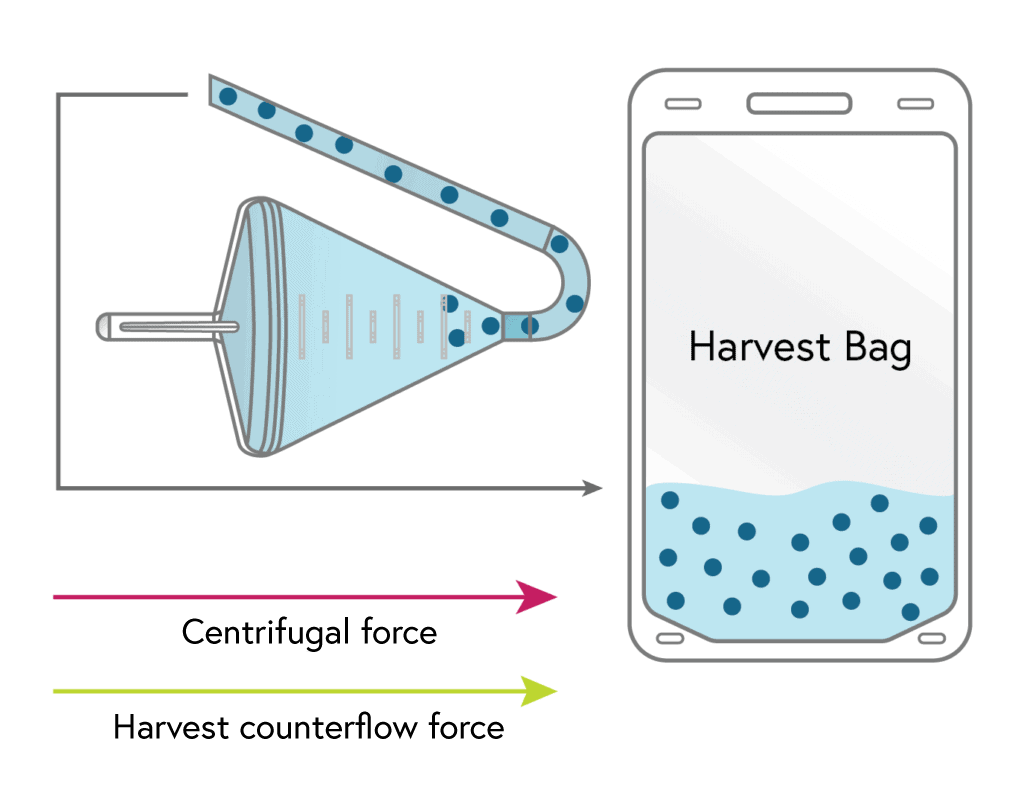

The Korus™ counterflow centrifugation system operates on the principle of elutriation. Elutriation is a process for separating cells based on their size, shape and density using a stream of fluid flowing in the opposite direction to the centrifugal force.

The benefits of elutriation are:

- Separation of target from non-target cells

- Gentle production of a non-pelleting cell bed