For allogeneic cell therapies to reach their therapeutic potential, challenges related to achieving scalable and robust manufacturing processes must be addressed. For example, cost of goods sold can be significantly reduced via true end-to-end automation enough to minimize the theoretical price gap between autologous and allogeneic cell therapies because labor costs will be reduced. In this article, we focus on allogeneic cell therapy costs as discussed in a recent Cell & Gene Live event.

The ‘Can Innovation Drive Down Cell Therapy Manufacturing Costs?’ on-demand webinar featured panelists Dr. Mark Gilbert, SVP of R&D of Acepodia; Thomas Lequertier, Head of Cell Therapy Manufacturing Unit of Celyad Oncology; and Ludek Sojka, Ph.D. Chief Technology Officer of SOTIO. The panelists discussed how both autologous and allogeneic cell therapies alike are impacted by the high cost of manufacturing.

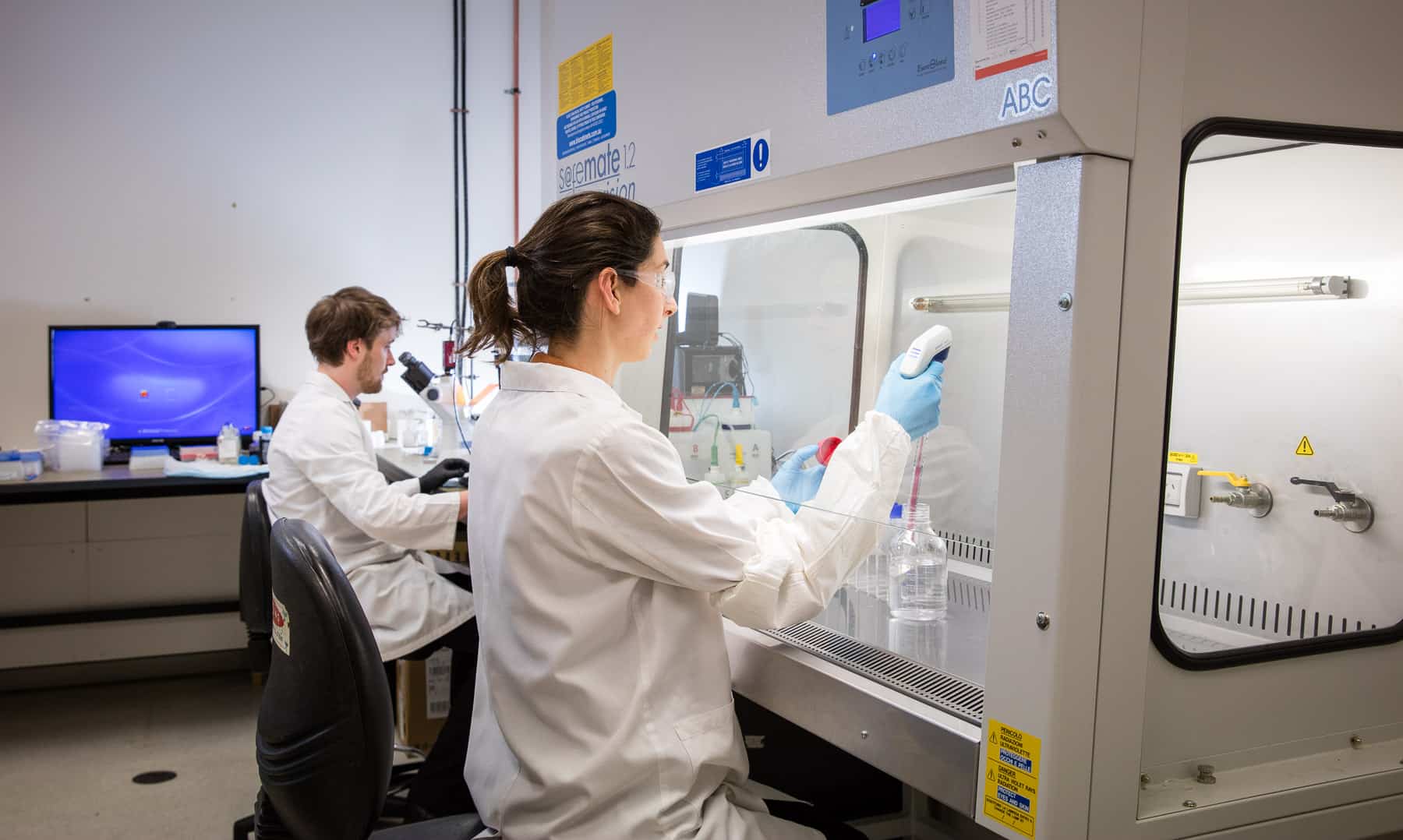

The highly specialized nature of the field requires ongoing workforce education and training that currently hikes up costs. “End-to-end automation is a must, because as of now, we need extensive labor to deliver the therapies,” explains Lequertier. Dr. Gilbert explained the following regarding autologous applications, but the same holds true for allogeneic therapies: “It is not easy to identify and recruit skilled technicians; and that has to change if we want to manage more than a several hundred thousand patients per year.”