For CGT developers, manual media formulation and preparation is one of the largest bottlenecks in CGT manufacturing followed closely by viral vector preparation.

Are these ancillary processes still pigeonholed as manual processes? “No,” says Randy Schweickart, Senior Director of Process Technology Development at Bristol Myers Squibb. “Now that we have some automated platforms, the scientists who are bringing the next pipeline product along can assume that we have those capabilities,” says Schweickart. “We are not working from the blank slate that we were [working from] when we started.” Similar to preclinical development, manufacturing process development has advanced significantly in the last several years.

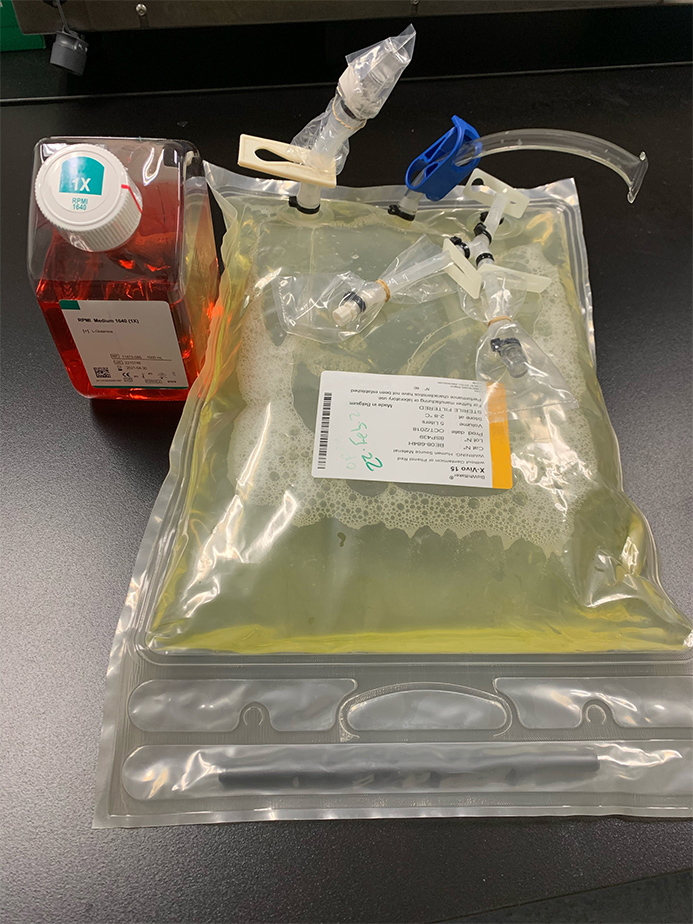

Platform processes have emerged, making it easier to ‘plug-and-play’ earlier in the development cycle. For example, bag filling platforms are available to accurately dispense therapeutic products or processing material from formulated bulk into individual bag units.

These automated platform systems provide the benefits of a closed system including reducing manufacturing overhead by moving processes to class C or D cleanrooms. With expanded closed system-based automation, a facility will no longer be burdened with a large quantity of expensive A or B cleanrooms to support ancillary processes.

Manufacturing facility designers should be consulted as early as possible, as production feasibility assumptions made by scientists may be outdated and automation solutions may be available. Amy Shaw, Lead of Cell Therapies Engineering and Automation at Takeda, affirms that to support manufacturing preparing for commercialization it is important to push as much of the upstream processes into the lower-grade spaces early in the timeline.

Shaw states, “If you can bring in ancillary materials that are closed and clean it relieves a lot of the constraints on the core processes.” Facility designers are now able to leverage automation systems instead of devising home-grown engineered solutions.