Make it simple. Reduce risk of harm. Reduce the potential for error. These are guiding principles when designing point of care (POC) diagnostic devices for CLIA Waiver.

Complex diagnostic tests that were previously performed by laboratory technicians or technologists are now being run by medical assistants, emergency medical technicians or patients themselves. This is possible because parts of the testing process that were previously performed by highly trained laboratory technicians have been automated. In a point of care setting, the tasks remaining for less-skilled clinical staff must be designed to be intuitive and in such a way that contamination, errors or other risks are reduced significantly.

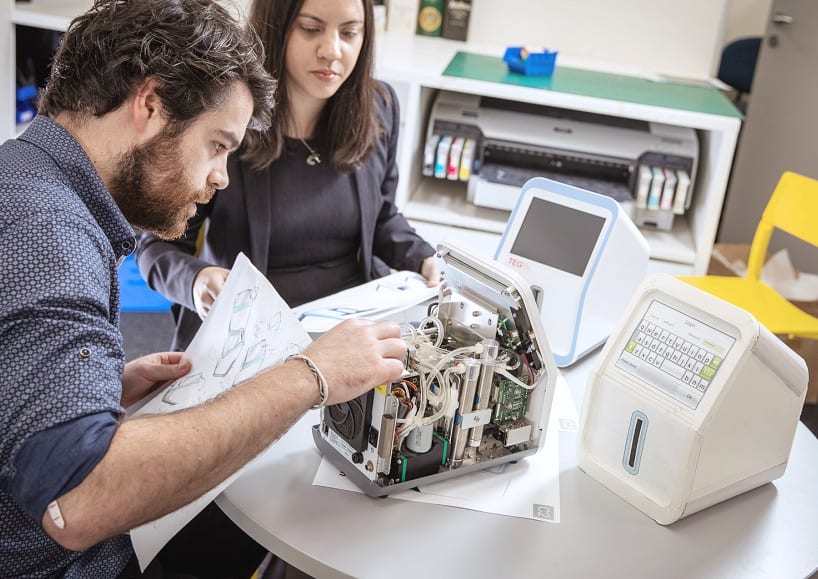

Making a complex test easy for end users is an interesting challenge and diagnostic device manufacturers must embrace good design principles to get it done. That means visiting user sites to understand aspects of the workflow and environment. Even more crucial is the effort to understand the needs of the people who will be handling the instrument through formative evaluations that test the device with real users.